Vortex grit chamber

ConsultationProduct overview: The equipment is generally used in the front of the primary settling tank and behind the bar screen of the municipal sewage treatment plant to separate the large inorganic particles in the sewage (the diameter is generally greater than 0.5mm).

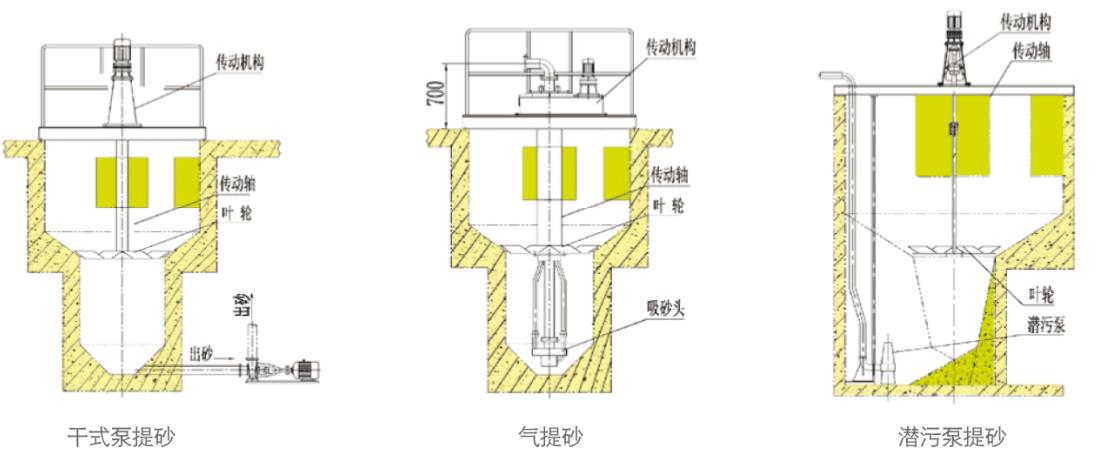

Product features: Most of them use air to lift sand. If sand pump is used to lift sand, the wear requirements are generally high. The steel tank body is suitable for small and medium-sized flow, which is applied to a single swirl grit chamber. When the gas lift sand is used, its combined structure function is similar to that of the dole grit chamber, but under the same treatment, the combined structure has small floor area and high efficiency.

Product Introduction

The equipment is generally used in the front of the primary settling tank and behind the bar screen of the municipal sewage treatment plant to separate the large inorganic particles in the sewage (the diameter is generally greater than 0.5mm). Most of them use air to lift sand. If sand pump is used to lift sand, the wear requirements are generally high. The steel tank body is suitable for small and medium-sized flow, which is applied to a single swirl grit chamber. When the gas lift sand is used, its combined structure function is similar to that of the dole grit chamber, but under the same treatment, the combined structure has small floor area and high efficiency.

Working principle

The raw water enters from the tangent direction, initially forming a swirling flow, forming a certain flow rate and flow pattern from the impeller, so that the sand adhering to the debris will gradually wash each other, and sink to the center of the hopper by the action of gravity and swirling resistance, and the stripped organic matter will overflow along with the axial water flow. The sand accumulated in the sand hopper is lifted by air or sand pump, and then enters into the sand water separator for complete separation. The separated sand is discharged to the garbage can (canister) for transportation, and the sewage is returned to the grid well.

Feature

1. Small footprint and compact structure. Good sanitation

2. The effect of sand setting is less affected by water volume, and the effect of sand water separation is good

3. The moisture content of the separated sand is low, which is convenient for transportation

4. PLC automatic control sand washing and discharging cycle, simple and reliable operation.

| Model | Capacity(m³/h) | Impeller speed (r/min) | Power(KW) | Water discharge (m³/h) | Inlet speed(m/s) | HRT(s) | Pump starting (t/d) | Sand removal property | Blower | ||

| Air flow(m³/min) | Pressure (Kpa) | Power (KW) | |||||||||

| XLC180 | 180 | 12-20 | 0.55-1.1 | 18 | 0.6-1 | 60 | 4(每次10min) | 比重>2.65;颗粒直径>0.1mm | 1.5 | 34.3 | 1.5 |

| XLC360 | 360 | 2.2 | |||||||||

| XLC720 | 720 | 34 | 2 | 39.2 | |||||||

| XLC1080 | 1080 | ||||||||||

| XLC1980 | 1980 | 12-20 | 1.1-2.2 | 40 | 2.5 | 44.1 | 3 | ||||

| XLC3170 | 3170 | 53.9 | 4 | ||||||||

| XLC4750 | 4750 | 48 | 2.8 | ||||||||

| XLC6300 | 6300 | 58.8 | |||||||||

| XLC7200 | 7200 | ||||||||||

| XLC9000 | 9000 | 72 | 3 | 69 | 7.5 | ||||||

| XLC12600 | 12600 | 78 | |||||||||

| XLC14400 | 14400 | 88 | 11 | ||||||||

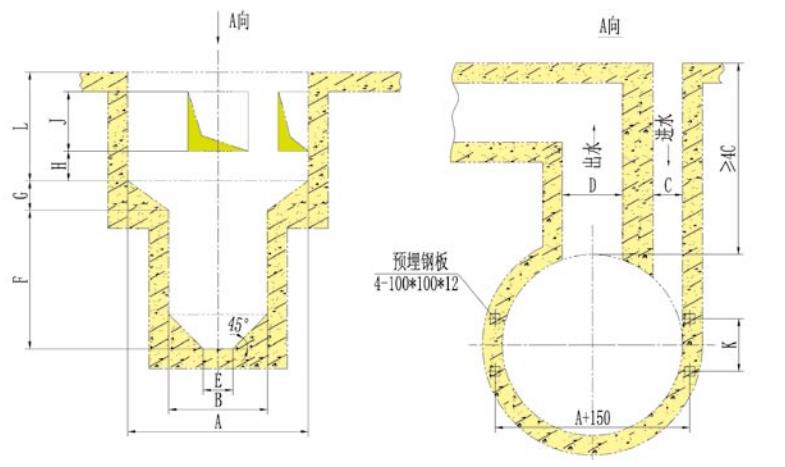

| Model | A | B | C | D | E | F | G | H | J | K | L |

| XLC180 | 1830 | 1000 | 305 | 610 | 300 | 1400 | 300 | 300 | 300 | 1100 | 1100 |

| XLC360 | 2130 | 380 | 760 | 1400 | 300 | 300 | 300 | 1100 | |||

| XLC720 | 2430 | 450 | 900 | 1550 | 400 | 300 | 400 | 1150 | |||

| XLC1080 | 3050 | 610 | 1200 | 1550 | 450 | 300 | 450 | 1350 | |||

| XLC1980 | 3650 | 1500 | 750 | 1500 | 400 | 1700 | 600 | 510 | 580 | 1450 | |

| XLC3170 | 4870 | 1000 | 2000 | 2200 | 1000 | 510 | 600 | 1850 | |||

| XLC4750 | 5480 | 1100 | 2200 | 2200 | 1000 | 610 | 630 | 1850 | |||

| XLC6300 | 5800 | 1200 | 2400 | 2500 | 1300 | 760 | 700 | 1950 | |||

| XLC7200 | 6100 | 1200 | 2400 | 2500 | 1300 | 760 | 750 | 1950 | |||

| XLC9000 | 7315 | 1875 | 3350 | 2515 | 1300 | 760 | 1675 | 2845 | |||

| XLC12600 | 8535 | 1980 | 3950 | 2895 | 1525 | 760 | 1980 | 3200 | |||

| XLC14400 | 8645 | 2130 | 4279 | 3050 | 1625 | 760 | 2135 | 3430 |

- Last article: no more;

- Next article: Sand water separator