Polymer Dosing Equipment

ConsultationProduct overview: The function of the dosing device is to dissolve the powder polymer into a solution

Product features: Automatci dosing or manual dosing are optional

Auto dosing equipment

Introduction

It integrates ingredients, dissolution and dosing into the body, fully automatic operation. The ingenious design of dry speculation and heating device can reduce caking phenomenon. The dosage and water inflow can be adjusted, and the required concentration of liquid medicine can be prepared at will. When the powder reaches the low level, an alarm signal will be sent out;

Optional: vacuum feeder, online dilution system;

Tank material: SS304, 316L, PP or FRP

Feature

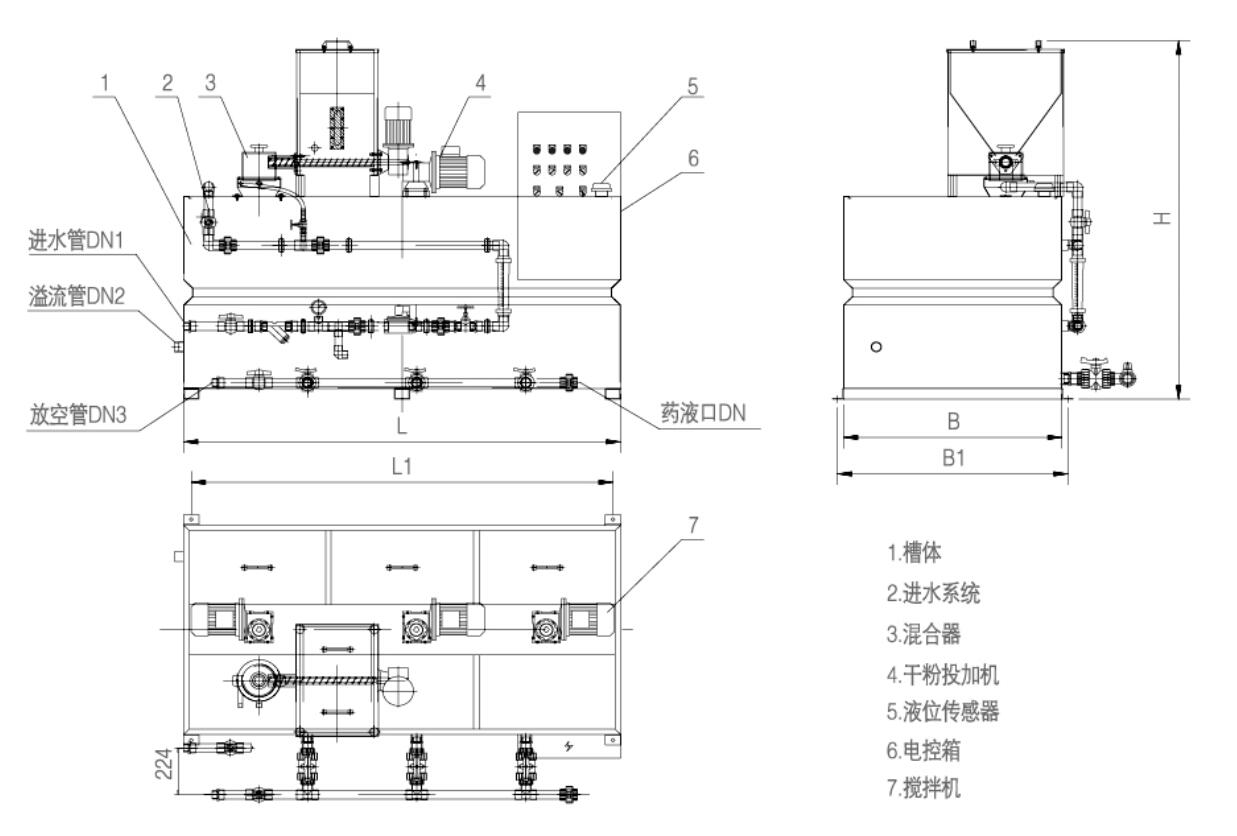

1. Three tanks (prefabricated mixing tank, homogenization tank and solution storage tank) are prepared continuously, with simple operation;

2. The influent flow can be adjusted, and the concentration of solution can be adjusted arbitrarily;

3. The ingenious design of dry speculative high-precision conveying and pre soaking device can reduce the generation of particle (block) phenomenon, reduce the waste of chemicals and avoid pipeline or equipment blockage;

4. The dry powder conveyor has the function of anti condensation, heating and heat preservation, which can effectively prevent the agent from moisture and agglomeration or deterioration;

5. The equipment automatically operates intermittently and stops cross stirring function to make the prepared solution mix evenly;

6. When the level of dry powder in the hopper is too low, an audible and visual alarm signal will be sent to remind the operator of feeding;

Manual dosing device

Introduction

Manual feeding, suitable for small dosage, presence of staff;

Manual feeding is easy and installation is convenient;

Can body, dosing pump, electric control box and pipe fittings are integrated and installed on the frame body, with compact structure and convenient installation and transportation

Tank body material: stainless steel SS304 or SS316L, polyethylene PE, FRP, etc

| Model | MYTH 500 | MYTH 1000 | MYTH 1500 | MYTH 2000 | MYTH 2500 | MYTH 3000 | MYTH 4000 | |

| Capacity (L/h) | Curing time/hr | 500 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Power ( kw ) | 1.7 | 2.45 | 2.45 | 2.45 | 3.5 | 3.9 | 3.9 | |

| PAM Dry powder dosing ( kg/h ) | 1~5 | 2~10 | 3〜15 | 3.5-20 | ||||

| Water inlet( m3/h ) | 0.3-1.5 | 0.6-3 | 0.9-4 | 1.2-6 | 1.6-8 | 2.0-10 | 2.4-12 | |

| Dimension (mm) | L | 1370 | 2000 | 2130 | 2200 | 2400 | 2400 | 2720 |

| B | 680 | 1000 | 1070 | 1200 | 1200 | 1300 | 1400 | |

| H | 1500 | 1710 | 1710 | 1900 | 2140 | 2180 | 2250 | |

| L1 | 1300 | 1930 | 2060 | 2130 | 2330 | 2330 | 2650 | |

| B1 | 730 | 1050 | 1120 | 1250 | 1250 | 1350 | 1450 | |

| Polymer inletDN | DN25 | DN32 | DN32 | DN32 | DN40 | DN40 | DN40 | |

| Water inlet DN1 | DN25 | DN32 | DN32 | DN32 | DN40 | DN50 | DN50 | |

| Overflow DN2 | DN32 | DN40 | DN40 | DN40 | DN40 | DN40 | DN40 | |

| Vent DN3 | DN25 | DN32 | DN32 | DN32 | DN40 | DN40 | DN40 | |

| Net weight ( kg) | 250 | 400 | 490 | 550 | 650 | 700 | 770 | |

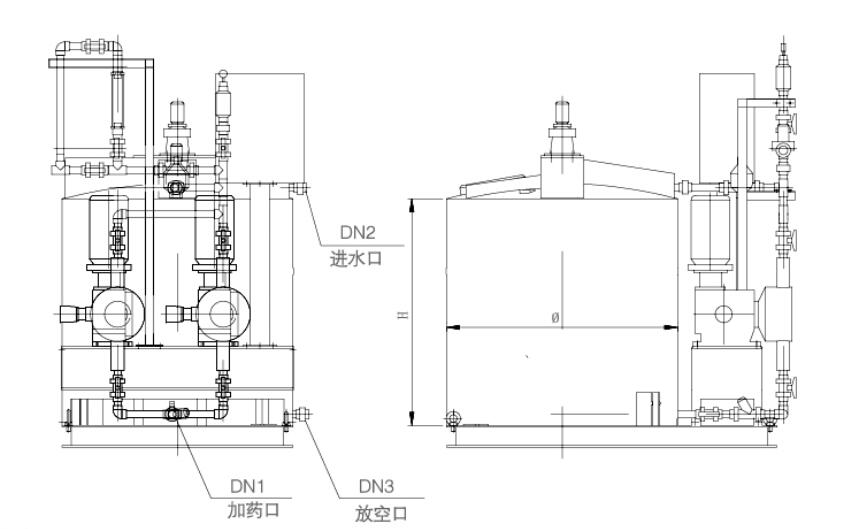

| Model | Volume (m³) | Mixing (kw) | Diameter ∅(mm) | Tank height H0 (mm ) | Polymer inlet DN1 (mm) | Water inlet DN2 (mm ) | Vent DN3 (mm ) |

| MJY1000 | 1 | 0.75 | 1050 | 1330 | 25 | 25 | 32 |

| MJY2000 | 2.0 | 1.5 | 1310 | 1720 | 25 | 25 | 40 |

| MJY3000 | 3.0 | 1.5 | 1550 | 1800 | 25 | 25 | 40 |

- Last article: no more;

- Next article: Screw Conveyor