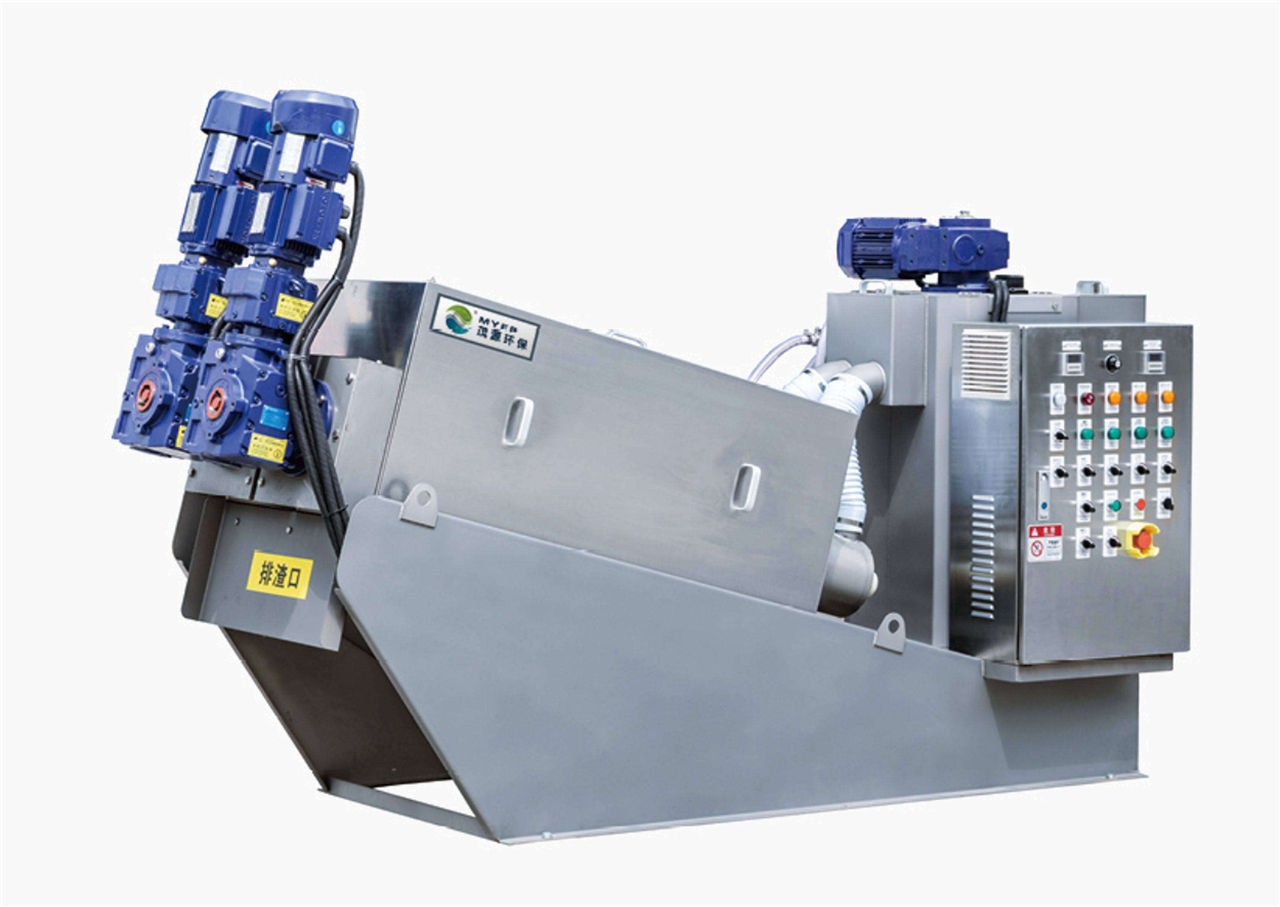

Screw Press Sludge Thickening Machine

ConsultationProduct overview: Main body of the Sludge thickening machine is consisted of moving rings and fixed rings, with a screw shaft inside, the equipment can run for 24 hours continuously.

Product features: High concentration efficiency, small footprint, closed operation, reducing odor generation Low speed, low energy consumption, low operation cost, low vibration, low noise Wide sludge concentration range, applicable to sludge moisture content range of 98% ~ 99.8%, and after concentration, sludge moisture content is stable and adjustable in the range of 90% ~ 96%

Product introduction

Product introduction

Compared with the screw press sludge dewatering machine, Screw press sludge thickener is also advanced in the low operating & maintenance cost, dewatering performance, smell protection,noise, automatic control, service life and laborintensity, etc. The sludge can be condensedrapidly and continuously in the secondary settling tank, meanwhile, after condensed and separated, the sludge concentration can be adjusted between 90% and 96% stably, there are many advantages after make use of this device, such as no need concentrated tank, small footprint, less cost, effectively reduce the odor & phosphorus release caused by sludge concentration tank, greatly improve the process capacity of sludge dewatering and deep drying treatment.

Applications

◆As the pre-treatment device of deep dewatering, also as the auxilary equipment of ulta high pressure filter press

◆Take place of sludge thickening tank, work as the pre-treat device of the sludge dewatering system

Technical Feature

◆High thickening efficiency, small footprint, closed operation, little odor

◆Low Speed, low noise, low power consumption

◆Wide sludge thickening range, water content of sludge : 98 ~99.8%, after the machine, the water content is in range 90~96% adjustable.

Product advantage

1、Wide application

Widely used for all industries include municipal, food, drink, slaughtering, printing, oil, paper, leather and chemical etc.

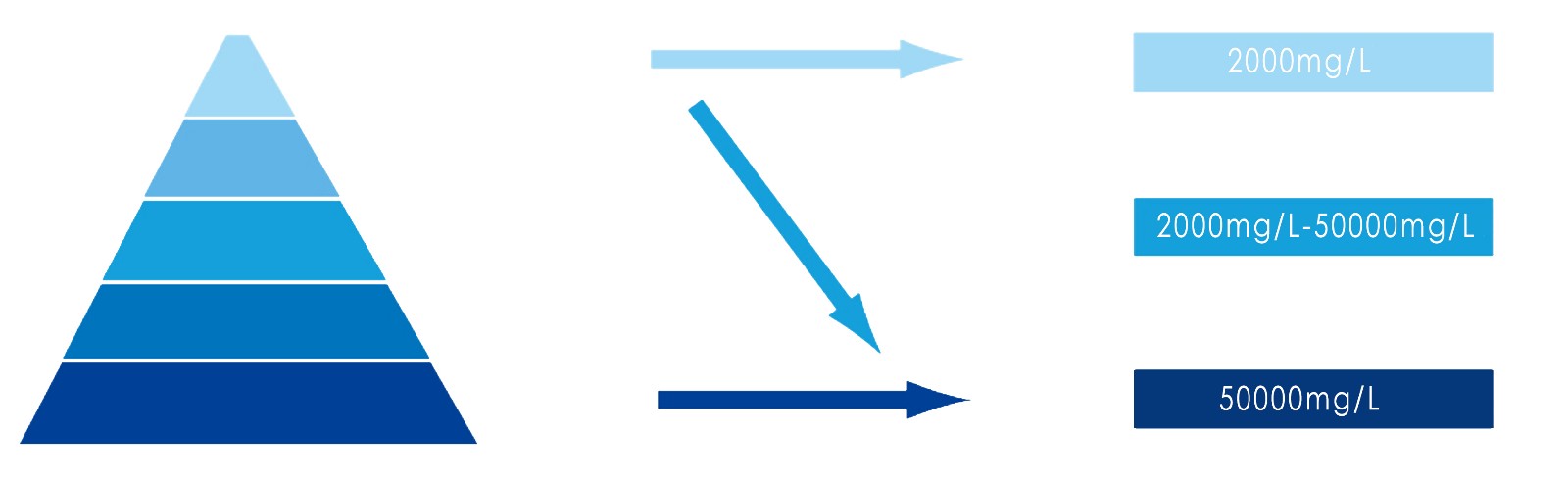

Special dewatering principle, makes this equipment suitable to handle high and low solids content sludge. TSS start from 2000mg/Lfirst dewatering unit that can treat the low solids content sludge.

Innovative structure design, makes the equipment suitable for all kinds sludge type. Especially oily sludge.

2、No clogging easily

Special structure of moving and fixed rings, makes the equipment not clogging easily, no need of large washing to prevent clogging. Save washing water and lower the internal burden.

![1576223189949378[1]](/en/Uploads/image/20200318/1584515159856649.jpg)

3、Continuous & automatic running

From sludge feed, polymer dose, cake discharge all controlled and connected together by the panel. For the first time, continuous running 24 hours a day is achieved.

4、Running cost saving

Low speed screw pressing technology, greatly reduce the electricity consumption, no clogging, greatly reduce the wash water, automatic no-man watching running, greatly reduce the labor cost.

5、No 2nd pollution

Speed of screw shaft is 2~3rpm, no vibration, low noise; The structure can clean itself, no clogging, no 2nd pollution; Slow running mode, the smell will not spread.

6、Durable and light structure

Direct mechanical dewatering, no need of rotary drum, so the machine is light; The machine is made completely by stainless steel, only screw shaft and moving rings need to be replaced. Longer lifespan.

7、Saving civil investment

As screw press is integrated with sludge thickening function. It can handle the sludge directly from the settling tank. No need of thickening or storage tank, so as to reduce the civil footprint and conscturction cost.

8、Improve phosphorus removal

Sludge is dewatered under aerobic condition, the phosphorus will not release like traditional sludge thickening tank. So to prove the phosphorus removal function of the whole system.

机型 | DS标准处理量 | 泥水混合物处理量 | 电机功率(kw) | 清洗用水量(L/h) | |||||

2500mg/L | 5000mg/L | 10000mg/L | 20000mg/L | 驱动电机 | 搅拌电机 | 合计 | |||

MYEP-N301 | 70~100kg/h | ~28m³/h | ~14m³/h | ~10m³/h | ~5m³/h | 0.75 | 0.55 | 1.3 | 40 |

MYEP-N302 | 140~200kg/h | ~56m³/h | ~28m³/h | ~20m³/h | ~10m³/h | 1.5 | 0.75 | 2.25 | 80 |

MYEP-N303 | 210~300kg/h | ~84m³/h | ~42m³/h | ~30m³/h | ~15m³/h | 2.25 | 1.1 | 3.35 | 120 |

MYEP-N304 | 280~400kg/h | ~112m³/h | ~56m³/h | ~40m³/h | ~20m³/h | 3 | 1.1 | 4.1 | 160 |

MYEP-N351 | 120~160kg/h | ~48m³/h | ~24m³/h | ~16m³/h | ~8m³/h | 1.1 | 0.75 | 1.85 | 60 |

MYEP-N352 | 240~360kg/h | ~96m³/h | ~48m³/h | ~32m³/h | ~16m³/h | 2.2 | 1.1 | 3.3 | 120 |

MYEP-N353 | 360~360kg/h | ~144m³/h | ~72m³/h | ~48m³/h | ~24m³/h | 3.3 | 1.5 | 4.8 | 180 |

MYEP-N354 | 480~480kg/h | ~192m³/h | ~96m³/h | ~64m³/h | ~32m³/h | 4.4 | 1.5 | 5.9 | 240 |

MYEP-N401 | 200~300kg/h | ~80m³/h | ~40m³/h | ~30m³/h | ~15m³/h | 1.5 | 1.1 | 2.6 | 80 |

MYEP-N402 | 400~600kg/h | ~160m³/h | ~80m³/h | ~60m³/h | ~30m³/h | 3 | 1.5 | 4.5 | 160 |

MYEP-N403 | 600~900kg/h | ~240m³/h | ~120m³/h | ~90m³/h | ~45m³/h | 4.5 | 1.5 | 6 | 240 |

MYEP-N404 | 800~1200kg/h | ~320m³/h | ~160m³/h | ~120m³/h | ~60m³/h | 6 | 1.1+1.1 | 8.2 | 320 |

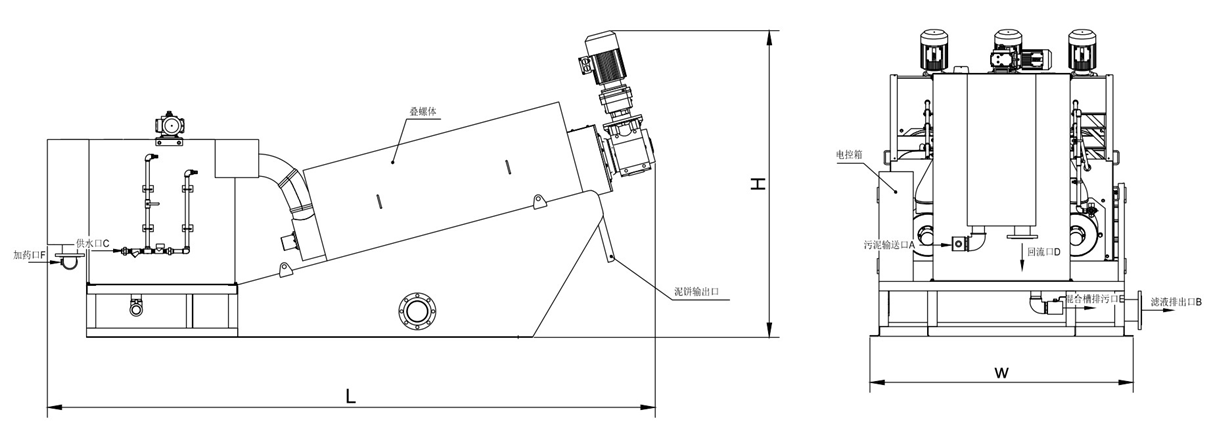

机型 | 泥饼排出口离地面距离(mm) | 外形尺寸(mm) | 污泥输送口(A) | 滤液排出口(B) | 供水口(B) | 回流口(D) | 混合槽排污口(E) | 加药口(F) | 净重(kg) | 运行重量(kg) | ||

长(L) | 宽(W) | 高(H) | ||||||||||

MYEP-N301 | 500 | 3160 | 1150 | 2000 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 850 | 1250 |

MYEP-N302 | 500 | 3360 | 1350 | 2000 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 1200 | 1900 |

MYEP-N303 | 500 | 3560 | 1600 | 2000 | DN65 | DN150 | DN20 | DN65 | DN50 | DN25 | 1750 | 2550 |

MYEP-N304 | 500 | 3700 | 2110 | 2000 | DN80 | DN150 | DN20 | DN100 | DN50 | DN25 | 2300 | 3400 |

MYEP-N351 | 520 | 3850 | 1200 | 2300 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 1030 | 1930 |

MYEP-N352 | 520 | 3950 | 1600 | 2300 | DN65 | DN150 | DN20 | DN100 | DN50 | DN25 | 1960 | 3110 |

MYEP-N353 | 520 | 4250 | 2000 | 2300 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 2890 | 4390 |

MYEP-N354 | 520 | 4400 | 2550 | 2300 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 3820 | 5420 |

MYEP-N401 | 660 | 4450 | 1400 | 2560 | DN65 | DN150 | DN20 | DN65 | DN50 | DN25 | 2090 | 4090 |

MYEP-N402 | 660 | 4650 | 1900 | 2560 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 3280 | 5780 |

MYEP-N403 | 660 | 4750 | 2550 | 2560 | DN80 | DN150 | DN20 | DN100 | DN50 | DN40 | 5170 | 7670 |

MYEP-N404 | 660 | 4850 | 3150 | 2560 | DN80 | DN150 | DN20 | DN100 | DN50 | DN40 | 6560 | 9060 |

- Last article: Mobile Sludge Dewatering System

- Next article: no more;