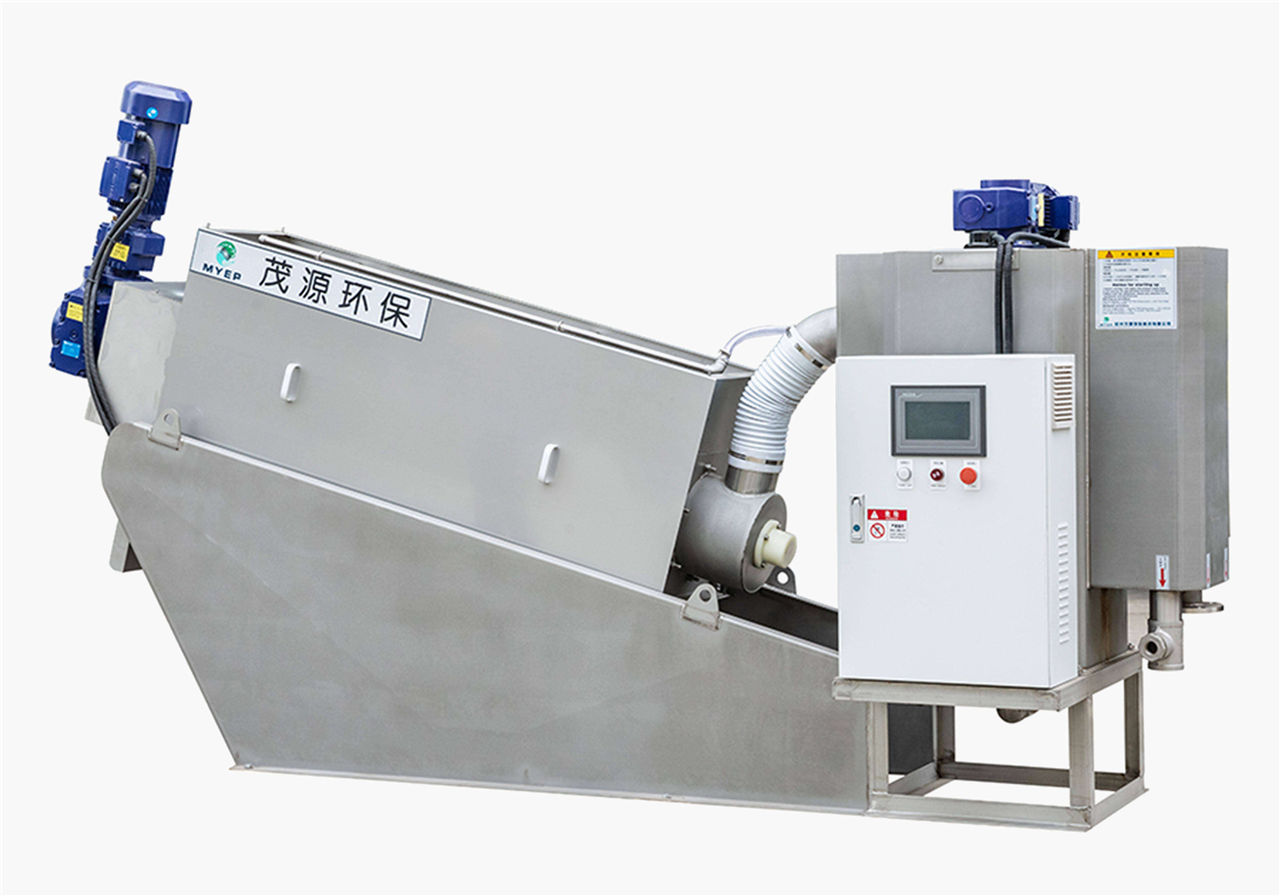

Screw Press Sludge Dewatering Machine

ConsultationProduct overview: By using the principle of screw extrusion, a new kind of solid-liquid separation equipment for sludge extrusion and dehydration is realized through the strong extrusion pressure caused by the change of screw diameter and screw pitch, and the tiny gap between the moving ring and the fixed ring.

Product features: Wide application, No clogging easily, Continuous running, Low running cost, No secondary pollution, Light frame, Saving civil engineering cost

Equipment Advantages

The Pre-thickening sludge dewatering machine is used for direct sludge dewatering:

1、This equipment is used for direct sludge dewatering (integrated thickening and dewatering machine). The sludge concentration can be 2000mg / L.

2、No clogging, reduce washing water consumption, save cost, and reduce internal circulation burden.

3、The control cabinet, flocculation mixing tank and main body are integrated to reduce the footprint, and the installation is simple and convenient.

4、The dewatering machine is in closed operation, and the treatment is stable and timely, so as to minimize the odor on site and improve the working environment.

5、24 hours continuous automatic running, low laborwork.

6、The screw shaft runs in low speed, low power consumption and basically no vibration and noise on site

7、Easy maintenance

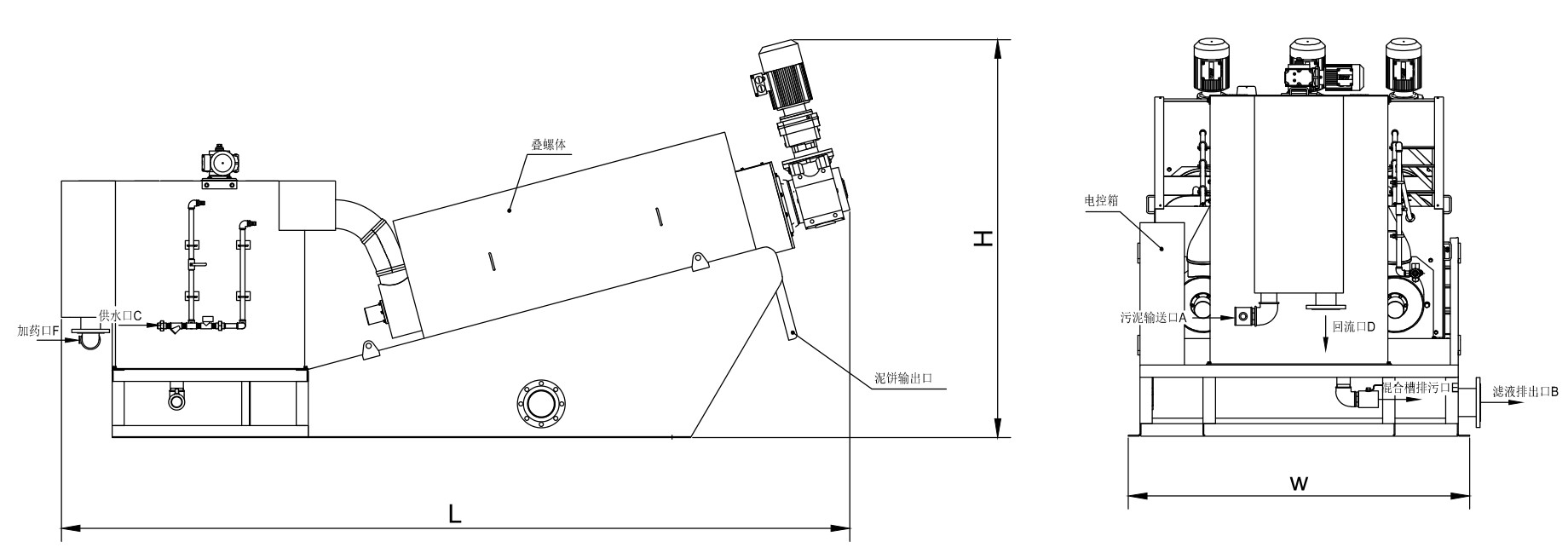

Structure

The main body of the sludge dewatering machine is composed of multiple fixed rings and moving rings, and the screw shaft runs through the filtration device formed therein. The former section is the thickening section, and the latter section is the dewatering section. The thickening and dewatering of sludge are completed in one cylinder, replacing the traditional filter cloth and centrifugal filtration mode.

Dewatering Principle

After gravity thickening in the thickening section, the sludge is transported to the dewatering section. In the process of advance, with the gradual decrease of the filter joint and pitch, and the blocking effect of the back pressure plate, a great pressure is generated, and the volume is constantly reduced, so as to achieve the purpose of fullly dewatering.

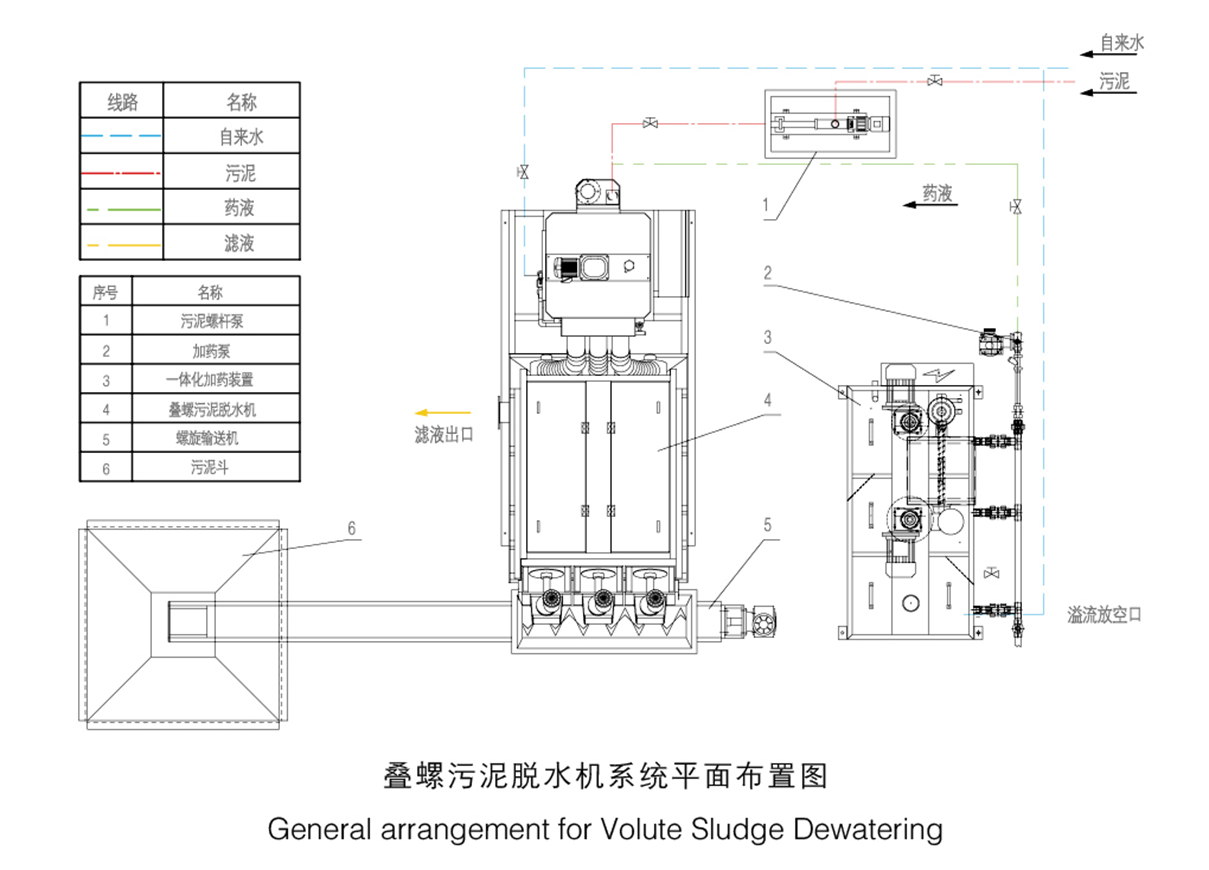

Process flow

Product Advantages

1、Wide application

Widely used for all industries include municipal, food, drink, slaughtering, printing, oil, paper, leather and chemical etc.

Special dewatering principle, makes this equipment suitable to handle high and low solids content sludge. TSS start from 2000mg/Lfirst dewatering unit that can treat the low solids content sludge.

Innovative structure design, makes the equipment suitable for all kinds sludge type. Especially oily sludge.

2、No clogging easily

Special structure of moving and fixed rings, makes the equipment not clogging easily, no need of large washing to prevent clogging. Save washing water and lower the internal burden.

![1576223189949378[1]](/en/Uploads/image/20200318/1584508717642074.jpg)

3、Continuous & automatic running

From sludge feed, polymer dose, cake discharge all controlled and connected together by the panel. For the first time, continuous running 24 hours a day is achieved.

4、Running cost saving

Low speed screw pressing technology, greatly reduce the electricity consumption, no clogging, greatly reduce the wash water, automatic no-man watching running, greatly reduce the labor cost.

5、No 2nd pollution

Speed of screw shaft is 2~3rpm, no vibration, low noise; The structure can clean itself, no clogging, no 2nd pollution; Slow running mode, the smell will not spread.

6、Durable and light structure

Direct mechanical dewatering, no need of rotary drum, so the machine is light; The machine is made completely by stainless steel, only screw shaft and moving rings need to be replaced. Longer lifespan.

7、Saving civil investment

As screw press is integrated with sludge thickening function. It can handle the sludge directly from the settling tank. No need of thickening or storage tank, so as to reduce the civil footprint and conscturction cost.

8、Improve phosphorus removal

Sludge is dewatered under aerobic condition, the phosphorus will not release like traditional sludge thickening tank. So to prove the phosphorus removal function of the whole system.

| Model | Dry sludge Capacity | Wastewater capacity | Power(kw) | Wash water consumption(L/h) | ||||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | Drive Motor | Mixing Motor | Total | |||

| MYEP131 | 10~14kg/h | ~1m³/h | ~0.5m³/h | ~0.4m³/h | ~0.3m³/h | ~0.28m³/h | 0.18 | 0.18 | 0.36 | 24 |

| MYEP201 | 15~20kg/h | ~1.5m³/h | ~0.75m³/h | ~0.6m³/h | ~0.5m³/h | ~0.4m³/h | 0.37 | 0.18 | 0.55 | 32 |

| MYEP202 | 30~40kg/h | ~3m³/h | ~1.5m³/h | ~1.2m³/h | ~1m³/h | ~0.8m³/h | 0.74 | 0.55 | 1.29 | 64 |

| MYEP203 | 45~60kg/h | ~4.5m³/h | ~2.25m³/h | ~1.8m³/h | ~1.5m³/h | ~1.2m³/h | 1.11 | 0.55 | 1.66 | 96 |

| MYEP301 | 50~70kg/h | ~5m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4m³/h | 0.75 | 0.55 | 1.3 | 40 |

| MYEP302 | 100~140kg/h | ~10m³/h | ~5m³/h | ~4m³/h | ~3m³/h | ~2.8m³/h | 1.5 | 0.75 | 2.25 | 80 |

| MYEP303 | 150~210kg/h | ~15m³/h | ~7.5m³/h | ~6m³/h | ~4.5m³/h | ~4.2m³/h | 2.25 | 1.1 | 3.35 | 120 |

| MYEP304 | 200~280kg/h | ~20m³/h | ~10m³/h | ~8m³/h | ~6m³/h | ~5.6m³/h | 3 | 1.1 | 4.1 | 160 |

| MYEP351 | 100~120kg/h | ~10m³/h | ~5m³/h | ~4m³/h | ~3m³/h | ~2.4m³/h | 1.1 | 0.75 | 1.85 | 60 |

| MYEP352 | 200~240kg/h | ~20m³/h | ~10m³/h | ~8m³/h | ~6m³/h | ~4.8m³/h | 2.2 | 1.1 | 3.3 | 120 |

| MYEP353 | 300~360kg/h | ~30m³/h | ~15m³/h | ~12m³/h | ~9m³/h | ~7.2m³/h | 3.3 | 1.5 | 4.8 | 180 |

| MYEP354 | 400~480kg/h | ~40m³/h | ~20m³/h | ~16m³/h | ~12m³/h | ~9.6m³/h | 4.4 | 1.5 | 5.9 | 240 |

| MYEP401 | 130~160kg/h | ~13m³/h | ~6.5m³/h | ~5m³/h | ~4m³/h | ~3.2m³/h | 1.5 | 1.1 | 2.6 | 80 |

| MYEP402 | 260~320kg/h | ~26m³/h | ~13m³/h | ~10m³/h | ~8m³/h | ~6.4m³/h | 3 | 1.5 | 4.5 | 160 |

| MYEP403 | 390~480kg/h | ~39m³/h | ~19.5m³/h | ~15m³/h | ~12m³/h | ~9.6m³/h | 4.5 | 1.5 | 6 | 240 |

| MYEP404 | 520~640kg/h | ~52m³/h | ~26m³/h | ~20m³/h | ~16m³/h | ~12.8m³/h | 6 | 1.1+1.1 | 8.2 | 320 |

| Model | Discharge height(mm) | Dimension(mm) | Sludge inlet(A) | Filtrate outlet(B) | Wash water(B) | Overflow(D) | Vent(E) | Polymer feeding(F) | Net(kg) | Running(kg) | ||

| Length | Width | Height | ||||||||||

| MYEP131 | 250 | 1940 | 730 | 1040 | DN40 | DN65 | DN20 | DN65 | DN40 | DN20 | 250 | 395 |

| MYEP201 | 350 | 2460 | 780 | 1370 | DN40 | DN80 | DN20 | DN65 | DN40 | DN20 | 420 | 540 |

| MYEP202 | 350 | 2540 | 970 | 1370 | DN40 | DN80 | DN20 | DN65 | DN40 | DN20 | 550 | 660 |

| MYEP203 | 350 | 2670 | 1230 | 1370 | DN40 | DN80 | DN20 | DN65 | DN40 | DN20 | 700 | 1010 |

| MYEP301 | 500 | 3340 | 920 | 1750 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 900 | 1300 |

| MYEP302 | 500 | 3530 | 1070 | 1750 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 1350 | 2000 |

| MYEP303 | 500 | 3680 | 1430 | 1750 | DN65 | DN150 | DN20 | DN65 | DN50 | DN25 | 1900 | 2700 |

| MYEP304 | 500 | 3830 | 1870 | 1750 | DN80 | DN150 | DN20 | DN100 | DN50 | DN25 | 2500 | 3600 |

| MYEP351 | 520 | 3850 | 2370 | 2040 | DN65 | DN150 | DN20 | DN65 | DN50 | DN20 | 1100 | 2000 |

| MYEP352 | 520 | 4100 | 170 | 2040 | DN65 | DN150 | DN20 | DN100 | DN50 | DN25 | 2100 | 3250 |

| MYEP353 | 520 | 4230 | 160 | 2040 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 3100 | 4600 |

| MYEP354 | 520 | 4230 | 2370 | 2040 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 4100 | 5700 |

| MYEP401 | 660 | 4540 | 1170 | 2110 | DN65 | DN150 | DN20 | DN65 | DN50 | DN25 | 2200 | 4200 |

| MYEP402 | 660 | 4810 | 1600 | 2110 | DN80 | DN150 | DN20 | DN100 | DN50 | DN32 | 3500 | 6000 |

| MYEP403 | 660 | 4810 | 2170 | 2110 | DN80 | DN150 | DN20 | DN100 | DN50 | DN40 | 5500 | 8000 |

| MYEP404 | 660 | 5010 | 2740 | 2110 | DN80 | DN150 | DN20 | DN100 | DN50 | DN40 | 7000 | 9500 |

- Last article: no more;

- Next article: Pre-thickening Screw Press Sludge Dewatering Machine