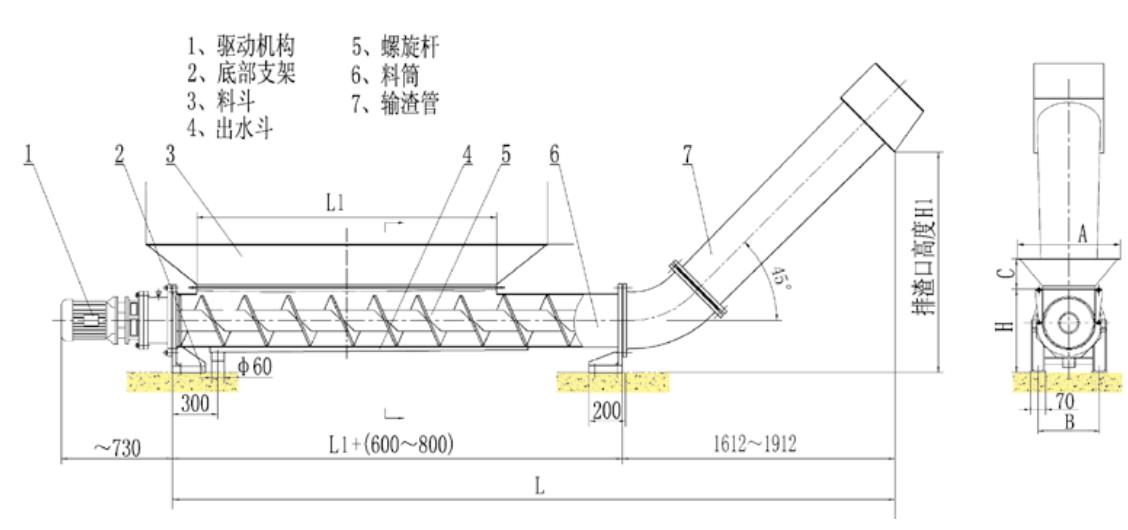

Screw Compactor

ConsultationProduct overview: Screw compactor is a supporting equipment of bar screen, which is composed of feed hopper, press screw, screw pipe, slag discharge pipe and driving device.

Product features: The screens or filtered residue from the bar screen is fed into the screw tube from the feed hopper, and is squeezed and dehydrated under the action of the pressing screw. The water permeable filter screen squeezed out from the material is collected into the water basin and discharged by the drainage pipe. After the material is compressed, it is discharged by the slag discharge pipe, so that the weight and volume of debris such as grid slag can be greatly reduced.

Product introduction

Screw press is a supporting equipment of trash rack, which is composed of feed hopper, press screw, screw pipe, slag discharge pipe and driving device. The grid residue or filtered filter residue from the grid is fed into the spiral tube from the feed hopper, and is squeezed and dehydrated under the action of the pressing screw. The water permeable filter screen squeezed out from the material is collected into the water basin and discharged by the drainage pipe. After the material is compressed, it is discharged by the slag discharge pipe, so that the weight and volume of debris such as grid slag can be greatly reduced.

Feature

◆Using shaft-less screw, low friction, can improve the extrusion efficiency. And there is no blockage and winding;

◆The equipment is made of stainless steel with high strength, good corrosion resistance and long service life;

◆The driving device adopts shaft mounted direct driving mode, which can run stably and reliably and save energy consumption;

◆Spring baffle is set at the outlet to increase extrusion pressure and increase dehydration rate;

◆Except for the inlet and outlet, the rest are sealed structure, and the use environment is clean and sanitary

| Model | Conveying load | Angle | (R/min) | Screw Diameter(mm) | Screw length(mm) | Power | Screen rate | A | B | C | H | H1 |

| YLY200 | 1.5 | 45° | 5-6 | 200 | 2.5≤L≤5.5 | 1.1-1.5 | ≥90% | 530 | 268 | ≥200 | 404 | 1200-1500 |

| YLY300 | 3 | 300 | 2.2-3 | 580 | 370 | 504 | ||||||

| YLY400 | 4.5 | 400 | 4-5.5 | 620 | 450 | 604 |

- Last article: SBR Decanter

- Next article: no more;